factory

All our compounds are manufactured In-House. We use only the finest Raw Materials to ensure that our finished product comes out in the standards of perfection we expect.

Our EPDM is imported from reputed companies in USA and Germany.

Other Processing Chemicals are sourced only from ISO Certified Companies in India.

It is this attention to detail of Raw Material that ensures our products meet the required specifications.

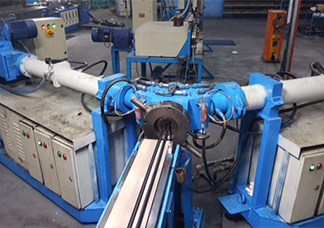

Our highly experienced design team is capable of designing any profile between 1mm and 140mm as per your requirement. We are industry leaders in speciality profiles Such as pre-cuts, notched, punched, perforated, and corded profiles.

All Dies are developed in-house. This ensures short turn around time, from when we receive your sample, to when we dispatch our counter-sample.

Since all dies are developed in-house, we ensure complete confidentiality, and we insist on signing a Non-Disclosure Agreement with your organization to guarantee confidence.

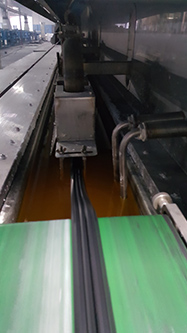

Our production team has over 25 years of International Experience in EPDM extrusion and are trained to follow only the Highest-Quality Standards in manufacturing.

We implement a cross-functional team approach during production, consisting of the Die Designer, Compounding Manager, Production Manager, and Sales Representative; to ensure that Customer Specific Requirements are met during production.